Lights on. Nuggs as rocks. Thumb-sized. No larger than that, or they will not fit in the packaging. Inside the grinder? They smash like cheese puffs. Coated in glandular crystals, ground, they look like a worm; you can see movement in waves of that glued plant material. Impossible to distinguish whether or not these flowers were grown indoors or outdoors.

From trap houses with hanging High Pressure Sodium lights -the same used in street lighting 25 years or so ago, to the current state-of-the-art greenhouse, lighting technology has expanded the quality of cannabis and blurred the distinction between indoor and outdoor cannabis.

Today, advanced greenhouses use both sunlight and artificial lighting, producing buds just as dense as indoor-grown. The terpene and cannabinoid richness once thought unique to outdoor crops can now be achieved at scale.

At its peak productivity, cannabis cultivation has become a kind of cyborg practice—half guided by nature’s sunlight, half engineered through artificial light. Sunlight delivers every wavelength plants need—the reds and blues that power photosynthesis, along with the subtler tones in between that shape how a plant stretches, flowers, and produces resin.

But if the sunlight is so good, why are growers supplementing light in their greenhouses? How do they do it? What are the best lights for this job? And how do they work?

More importantly, how are companies managing to undercut weed prices while still achieving indoor-quality flower at a fraction of the cost?

The Light Recipe

One of the most important aspects of supplementing light in greenhouses is finding the right amount of light and colors to achieve a certain objective, whether that is flowering or growing plants.

The different configurations of light spectrum in greenhouses, that is, the combination of wavelengths—or colors of light such as blue, red, and far-red— can vary as a recipe from a cookbook.

In pursuit of the perfect spectrum, cannabis growers are now chasing light deeper into the deserts of California. And Green Horizons is one of the cannabis companies, operating a one-million-square-foot campus, with the potential to produce about 350,000 pounds of sun-assisted cannabis every year.

In the words of Dillon Patterson, designer and operator of Green Horizons’ top-notch facility, one of the keys to an optimal light recipe is to focus on certain metrics, such as DLI, PPFD, and micromoles.

DL… what? Ok. Let’s break it down.

DLI stands for Daily Light Integral. “That is a calculation of photons to canopy over a period of time,” Patterson explained.

To make sense of what Patterson is describing, it helps to start with the basics: a photon is the smallest unit of light energy, like a single grain of sand on a beach. Plants don’t use light in big chunks; they take it photon by photon. So, DLI is really just a way of measuring how many of those tiny packets of light reach the plant’s canopy over the course of a day.

Sun-assisted cannabis grows work with a base DLI, a middle ground for vegetation and flowering, around 40 DLI. During the winter, when the DLI drops to 22, LED lights come into play. “That is what you would try to achieve in an indoor grow,” Patterson explained. “We based our calculations on the difference between what sunlight provides and what the plants still need, keeping it consistent with the light levels you’d expect in an indoor grow.”

“We designed our lights and our supplemental PPFD to the canopy based on that margin and that supplemental light. That margin is usually 700 PPFD in the winter and is basically a measure of the photons that are reaching the canopy.”

Bear with me on this one—it might sound like a physics lesson, but I promise it’s not. We’re not diving into a textbook; we’re just breaking down the language growers use to measure light. And once you see how simple it really is, you’ll understand exactly what Patterson means when he talks about PPFD hitting the canopy.

PPF, or Photosynthetic Photon Flux, refers to the total number of photons a light source emits each second. PPFD, or Photosynthetic Photon Flux Density, translates that number into what really matters: how many photons actually reach the canopy per square meter each second.

For practical cultivation, PPFD is the figure growers track most closely because it directly reflects the usable light available for photosynthesis.

In other words, Patterson is saying they calculate how much natural sunlight the plants are missing and then add just the right amount of artificial light to make up the difference. PPF tells you what a fixture produces in total, while PPFD shows how much of that output the plants are actually getting. And if PPFD is the light’s strength at a moment in time, DLI is the total light the plant collects over the whole day.

Greenhouse Location

Every light recipe depends on the grower, location, and technology available. In summer, natural sunlight can often meet the light requirements, but in winter or in regions with shorter daylight, growers turn to supplemental fixtures such as LEDs or high-pressure sodium lamps.

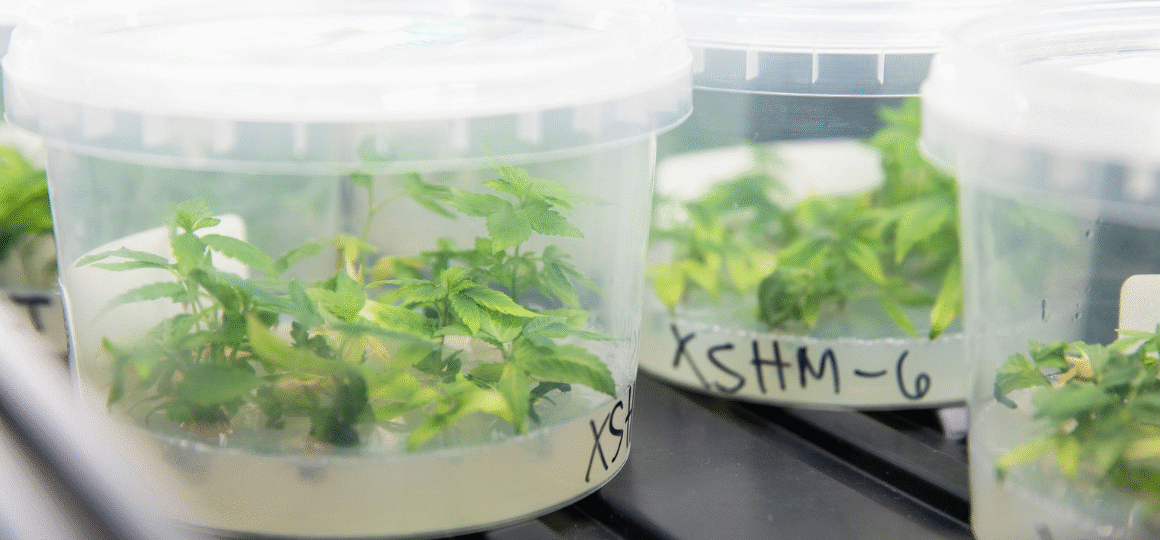

Because cannabis is photoperiod-sensitive, lighting is also used to extend day length and hold plants in a vegetative state, particularly for mother plants or clone production.

In line with Patterson, Martin Anker, founder and CEO of SANLight, one of the largest LED horticulture manufacturers in Europe, noted that Cannabis typically requires about 900 micromoles of light intensity sustained over 12 hours—equal to roughly 38 DLI per day—to develop dense buds.

For anyone unfamiliar with the unit, a micromole is simply a way of counting photons landing on the leaves, much like measuring how many raindrops hit a square meter every second.

Taylor Kirk, an agronomist at Fluence, a leading LED lighting brand, echoed Patterson and Anker’s observations. He noted that the ideal range falls between 40 and 50 DLI, which translates to about 500 to 1,000 PPFD depending on location. In line with their views, Kirk emphasized that while hitting these numbers is critical, the true efficiency of a lighting system also depends on how well reflectors and optics distribute photons evenly across the canopy.

With so many LED options out there, it can feel like staring at a constellation—thousands of points of light, hard to tell apart. Between hardware specs, power consumption, wiring, weatherproofing, and even microchip components, how do you decide which setup actually makes sense for your grow?

Customer service, quality of the components, and linear lights specifically designed for overhead supplemental lighting in greenhouses are the go-to options for Patterson. Green Horizons is equipped with dual-channel spectrum controls that let them adjust white, blue, and red lights independently, to support either plant growth or flowering.

These lights limit the shadow effect to get a uniform PPFD map. “We choose lights that allow us to get the highest uniformity, with dual channels, not a fixed spectrum, to control white, blue, and reds,” Patterson noted.

Anker, CEO of SANlight, added that growers shouldn’t get lost in the endless online debates about diodes. Technology doesn’t actually change every month; the best chips today are largely the same as they were two years ago.

Anker highlighted that what matters most is matching the chip type to the target spectrum. “For white light, mid-power LEDs driven at around 0.2 watts each perform best, while for red light, high-power LEDs are superior. That’s why most professional fixtures combine the two: white mid-power LEDs paired with red high-power LEDs,” Anker noted.

The details of reflector materials also play a huge role in performance. Inside each LED package, light is emitted in all directions, so it relies on an internal reflector. Anker warned that Cheaper plastic reflectors are inefficient, while silver reflectors perform better but degrade under humidity or sulfur.

Titanium oxide reflectors, by contrast, are the most stable and long-lasting, making them the gold standard.

According to Anker, “only a handful of companies currently produce mid-power LEDs with this reflector type, including Samsung (LM301H, LM301 EVO), Seoul Semiconductor (3030C series), and Osram.”

But as Anker cautioned, not every diode advertised as “Samsung” is high-end — Samsung manufactures hundreds of models across different efficiency levels. “For red light, Osram has long led the field with its Oslon Square Gen 6+ series, which remains the benchmark for high-power red LEDs,” Anker said.

Meanwhile, Kirk advises light shoppers to search for lights that can withstand pressure washing, support high heat, have dynamic fixtures to maximize use within the greenhouse, and have consistent customer service.

Intercanopy Lighting

Because more light is never a bad thing, mixed-lights cannabis grows are incorporating lights where the sun won’t shine, and that is, under the canopy. But, is this effective? Or is this part of the Instagram and TikTok frenzy because they just look like spaceships levitating between the buds?

For Patterson, lights under the canopy complement overhead lighting by reaching parts the overhead setting can’t reach and stimulating the production of lower buds, which grow bigger and denser.

In addition, intercanopy lights reduce the need for constant pruning, extra labor, and shorten production times. In other words, they help improve the ratio of “A buds,” the top nugs that naturally get the best light, to “B buds,” the smaller, lower flowers that usually develop with less density.

“The thing behind inner canopy lighting is it helps your A to B ratio, and it allows you to increase the size and maturity of the flowers inside the canopy that do not receive the light from above. Inner canopy lights make your lower buds of a higher quality—about 25% more bud can be grown with inner canopy lighting,” Patterson said.

This technology has a direct multiplier effect on revenue. A-grade buds can sell for as much as $750 per pound, while smaller B-grade buds bring closer to $200 per pound. By lifting the quality of lower buds, growers can effectively undercut the indoor flower market, producing what’s considered indoor-quality A-grade flower at a fraction of the cost and in nearly half the time.

Kirk also highlighted the sustainable advantage of intercanopy lights: “Because you’re only using what you need after accounting for the sun’s contribution, you’re working with nature as it exists in a particular region. In photosynthesis, there’s a source–sink relationship: light energy is captured by the leaves, then moved into other tissues for growth.” Kirk noted.

“By directing light into the shaded regions of the canopy, we can maximize photosynthesis and increase bud size where it normally wouldn’t happen. That means more flowers that can make it onto shelves, instead of being used as a byproduct, for extractions, for example.”

High-Pressure Sodiums Vs. LEDs

Within the greenhouse world, there’s a long-running debate: should growers rely on traditional high-pressure sodium (HPS) or metal halide lamps, or move to LEDs? Which is better for flowering? Is old-school necessarily better?

According to Anker, the answer is clear when you look at a specific metric: Micromoles per joule. Micromoles per joule (µmol/J) is a measure of efficiency—it tells you how many photons useful for photosynthesis (in micromoles) a light fixture produces for every joule of electricity consumed. In other words, it’s about how much usable light you get per unit of energy spent.

He explained that single-ended HPS—the common “screw-in” bulb—offers about 1.7 µmol/J at the bulb, but once you account for ballast and reflector losses, the real system efficiency drops to around 1.3–1.4 µmol/J.

For example, a 1,000-watt single-ended HPS typically draws about 1,100 watts at the wall and delivers a PPF of roughly 1,430 µmol/s. Double-ended HPS performs better, with system efficiency near 1.8 µmol/J and output closer to 1,980–2,000 µmol/s at the same power draw. Still, both remain significantly less efficient than modern LED systems.

By contrast, efficient LED fixtures operate at around 2.7 µmol/J, and their greenhouse-optimized spectra can exceed 3.0 µmol/J. That’s nearly double the efficiency of single-ended HPS, meaning growers can often achieve the same PPFD with about half the energy cost.

Another key difference lies in thermodynamics. Roughly 30% of HPS input power becomes light, while a large portion converts to radiant heat that directly warms plant leaves, with the rest dispersing as convective heat.

“LEDs also convert all of their energy into light and eventually heat, but they deliver far less radiant heat to the canopy. Instead, more heat accumulates at the fixture itself, which can be managed with airflow or greenhouse structure. For growers, this shift means the overall heat load may be similar, but its distribution—and its effect on plant leaves—is very different,” Anker noted.

Replacing HPS With LEDs

Anker pointed out that LEDs generate more convective heat at the fixture and far less radiant heat onto the canopy, which changes how leaf temperature behaves.

This distinction matters for both plant response and climate control. When replacing HPS with LEDs on a one-to-one wattage basis, the higher efficiency of LEDs means the canopy actually receives nearly double the PPFD. Those extra photons also warm the leaves, so despite the lower radiant heat, leaf temperature can still run higher under LEDs.

But if the objective is energy savings, the approach shifts. For example, if you replace 500 µmol/m²/s of HPS lighting with 500 µmol/m²/s of LEDs, you only need about 500 watts of LED power—roughly half the energy.

In this scenario, the total heat load decreases, which can lower leaf temperatures. That drop is most noticeable in early vegetative stages, when insufficient leaf warmth can lead to issues such as calcium uptake problems.

No Fixed Recipes

Indistinguishable from flowers grown strictly indoors, these greenhouse-grown buds are proof that mixed-light cultivation is here to stay — and that it’s changing the game.

Patterson, Anker, and Kirk agreed that there is no universal light recipe. The key lies in crafting a spectrum that matches the crop and location — and with the sun already providing much of the heavy lifting, supplemental fixtures can be tuned more precisely and used more sparingly. That combination means indoor quality flowers at a fraction of the cost.

But lighting is only part of the story. Controlled-environment greenhouses reduce costs through a suite of efficiency measures: less dependence on HVAC, evaporative cooling instead of energy-hungry chillers, runoff recovery and recirculation, water-saving irrigation systems, automated shading, smart venting, CO₂ enrichment, precision fertigation, integrated pest management, and climate-responsive controls. Together, these technologies push yields higher while pulling expenses down.

What works in the Coachella Valley won’t be the same as Northern Europe, and the balance of sun and supplementation will always shift with season and strain. Yet the pattern is clear: greenhouses are undercutting weed prices by blending sunlight with technology in smarter, more efficient ways.

The outcome is not just higher yields but consistent quality that blurs the old categories of indoor and outdoor.

Photos: Courtesy of Fluence, SANLight, and Green Horizons.